CLEAN ROOM DESIGN: CONSTRUCTION

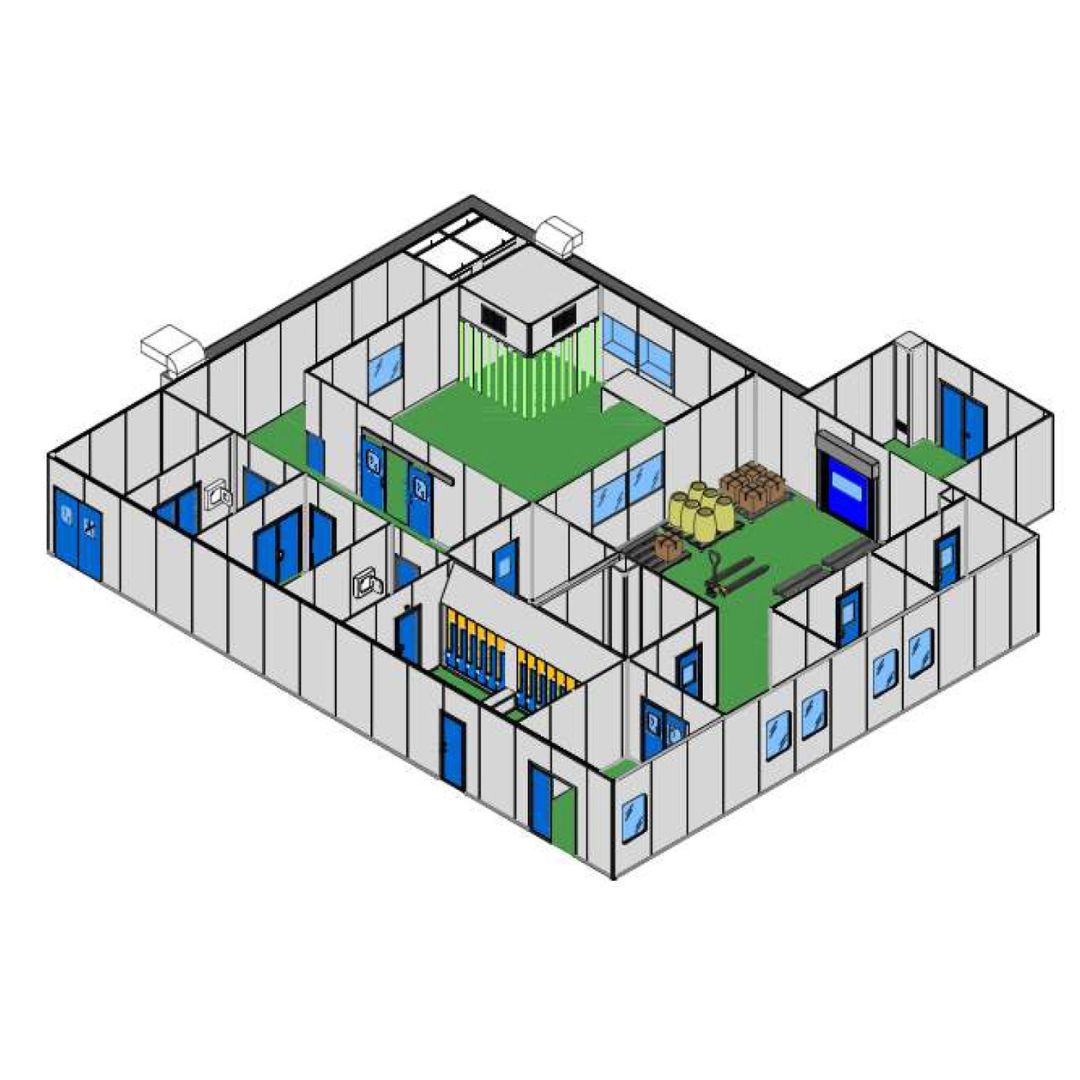

In clean rooms, the need to focus the design and construction of interior enclosures on the non-generation of pollution requires the development of an interior architecture system that, through the use of

materials and specific solutions, achieve ideal finishes and total integration of the rest of the facilities.

In this sense and based on the applicable regulations, we created the “TECNIPURE SYSTEM”, thought as a whole as a global system of enclosures (walls, ceilings, doors, windows, floors and accessories),

which allows us to offer the most innovative and appropriate technical solutions in a Clean Room installation.

Walls

The set of partitions is made up of sandwich panels with a symmetrical formation and a smooth surface. They are self-supporting, easily removable and are assembled together using a hollow aluminum inner tube that is used for the passage of small installations. They can be panels finished in phenolic resin or metal sheet. Both are manufactured from a stable rigid support (polystyrene, PIR, rock wool, depending on needs) with variable density depending on its use, which is glued in the factory with solid plates of thermostable synthetic resin:

TECNIPURE RESIN PANEL or smooth pre-lacquered metal sheet:

TECNIPURE SHEET PANEL. In both cases, the outer plates are completely separated to avoid possible thermal bridges.

Doors

We manufacture several models of swing doors (R, PE, PEA, PER,) specific for use in clean rooms. Its standard finish is with a phenolic resin plate, although in special conditions of

temperature or humidity, it is possible to create doors with a lacquered sheet metal finish.

We have sliding doors, specific roll-up doors for clean rooms that are watertight and self-repairing, as well as inflatable seal doors for environments with

maximum tightness requirements.

All door models allow the possibility of incorporating a wide variety of

accessories such as: round or rectangular peepholes, electric and magnetic interlocks, traffic lights (as a complement to the interlocks), automatic weather stripping, exterior and hidden door closer springs,

panic bars, motors, alarms, access control, protections, stainless accessories, locks, trained light bulbs...

Windows

There are different models of windows within the “TECNIPURE SYSTEM”:

– With interior frame: These are windows that have an interior aluminum frame white lacquered. They can be rectangular (with straight corners) and dimensions that adapt to the modulation of the panel or rounded (with curved corners con radio 100 mm).

– Without interior frame: They are windows with rounded corners that are made with numerical control equipment. They are made without any aluminum frame and Its standard dimensions are 950 x 1200mm, although if necessary They can be made to measure.

The windows used within the “TECNIPURE SYSTEM” are watertight, well-flush and have 5 mm double glass. of thickness.

During assembly, a 3mm joint is left throughout. Its perimeter is sealed with polyurethane mastic.

They can have laminated or safety glass, as well as polycarbonate, depending on the specifications on needs.